In many water supply systems, maintaining a stable liquid level is essential for safety, energy efficiency, and overall system performance. Among the various level-control devices available, the float control valve stands out for its reliability, simplicity, and ability to operate without external power. As industries move toward smarter and more efficient fluid management, understanding how this valve works—and the advantages it brings—has become increasingly important.

What Is a Float Control Valve

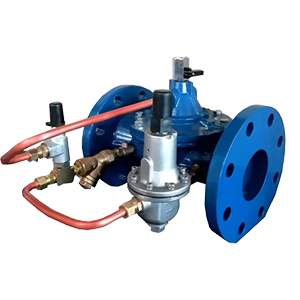

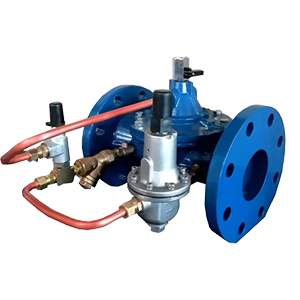

A float control valve is an automatic, hydraulic-operated valve used to regulate the liquid level in tanks, reservoirs, towers, and cisterns. It relies on a mechanical float that senses changes in water level. As the liquid level rises or falls, the float moves accordingly, opening or closing the valve to maintain a preset water level.

Unlike electrically controlled level switches or pump systems, float control valves operate purely on fluid pressure and mechanics, making them highly reliable in remote or power-limited locations.

Key Components

-

Pilot float assembly – Detects water level changes

-

Main valve body – Controls the flow of water

-

Linkage mechanism – Transfers float movement to the valve

-

Diaphragm or piston – Opens or closes the valve according to pilot pressure signals

This simple yet effective design ensures stable and accurate level control with minimal maintenance.

How a Float Control Valve Works

The working principle centers on the movement of the float:

-

When the water level drops, the float lowers, sending a signal to open the valve. Water flows into the tank.

-

When the water level reaches the set height, the float rises and signals the valve to close, stopping water inflow.

This automatic cycle prevents both overflow and dry running, ensuring every system remains in its optimal operating range.

How Float Control Valves Improve Fluid Management Efficiency

1. Prevents Overflow and Water Loss

Valves open and close at the correct moment, eliminating tank overflow. This helps facilities reduce water wastage, avoid surface flooding, and maintain safer working environments.

2. Stabilizes System Pressure

Maintaining a constant water level helps stabilize pressure throughout the pipeline. This is especially beneficial in municipal networks, cooling towers, and industrial circulation systems.

3. Reduces Energy Consumption

Because the valve operates passively, it does not require electricity, sensors, or control panels. Water flows only when needed, reducing pump runtime and extending equipment life.

4. Protects Pumps and Downstream Equipment

A stable water level prevents:Pump cavitation.Air intake.Sudden pressure surges

These protective effects greatly improve operational reliability.

5. Enhances System Automation

Float valves work automatically without human intervention. Once installed and calibrated, they provide continuous, hands-off control—ideal for remote sites or unattended facilities.

6. Low Maintenance and Long Service Life

With fewer electronic parts and a simple mechanical structure, float control valves require minimal maintenance. Their robust design ensures stable performance even in harsh environments or variable water quality conditions.

Typical Applications

Float control valves are widely used across sectors where consistent water levels are vital:

-

Water tanks and reservoirs

-

HVAC cooling towers

-

Industrial process tanks

-

Irrigation and agricultural water systems

-

Elevated water towers

-

Municipal distribution systems

-

Fire protection storage tanks

Their versatility makes them suitable for both small commercial installations and large-scale industrial infrastructure.

Why Float Control Valves Matter for Modern Fluid Systems

As industries shift toward smart, efficient, and sustainable fluid management, devices that offer both reliability and simplicity have become extremely valuable. For engineers and system designers, they remain a trusted solution for level control, pressure stability, and energy-efficient operation.

.png)

en |

en |