What is a Needle Valve

A needle valve is a type of valve designed for precise regulation of fluid flow. Unlike ball or gate valves, which are better suited for quick on/off operations, needle valves allow gradual and accurate adjustments.

The valve is named after its internal structure. At the core lies a long, tapered needle-like stem that fits into a matching seat. As the stem moves downward, the pointed tip gradually restricts the passage of liquid or gas. As it moves upward, flow increases in a controlled manner.

This geometry makes the needle valve particularly useful when systems require fine-tuning rather than full shutoff or simple isolation.

How Does a Needle Valve Work

The working principle is straightforward yet highly effective.

-

When the handwheel or actuator is turned, the stem moves up or down.

-

The tapered needle tip either enters or withdraws from the valve seat.

-

This incremental movement adjusts the orifice opening, controlling the rate of flow with precision.

A helpful analogy is comparing a needle valve to a dimmer switch. While a ball valve works like a light switch—either on or off—the needle valve acts like a dimmer, allowing the operator to fine-tune flow levels between minimum and maximum.

Because of this precision, needle valves are not usually chosen for applications requiring high flow rates. Instead, they excel in low-flow, high-pressure, or calibration-sensitive situations.

Key Applications of Needle Valves in Piping

1. Flow Regulation in Instrumentation Systems

Needle valves are frequently used in instrumentation and control systems where small, accurate adjustments are necessary. For example, they can regulate the flow of fuel to burners or the delivery of air in pneumatic systems.

2. Pressure Control

In high-pressure environments, such as oil and gas pipelines, needle valves help manage pressure by allowing gradual flow adjustment without sudden surges that could damage equipment.

3. Chemical and Petrochemical Processing

Needle valves are often used with corrosive or hazardous fluids in chemical plants. Their ability to provide secure, leak-tight shutoff ensures safe operations even in challenging environments.

4. Hydraulic and Pneumatic Systems

In hydraulic machinery, needle valves regulate the rate at which fluids move through circuits. In pneumatics, they help control airflow, impacting the speed of actuators and cylinders.

5. Laboratory and Testing Equipment

Because of their precision, needle valves are also used in laboratories and pilot plants where exact measurements of flow are crucial to research and testing.

Advantages of Needle Valves

Precision Control: Allows operators to fine-tune flow in small increments.

-

Reliable Shutoff: The needle-to-seat contact ensures tight sealing in many designs.

-

Durability in High-Pressure Applications: Especially when made of stainless steel or other robust alloys.

-

Versatility: Suitable for both gases and liquids, and adaptable to corrosive media with the right materials.

Limitations of Needle Valves

Not for High Flow Rates: Their small orifice limits the amount of fluid that can pass through.

-

Slower Operation: Unlike ball or gate valves, needle valves are not designed for rapid shutoff.

-

Wear with Abrasive Media: If used with particles in the flow, the seat and needle may wear down more quickly.

Materials and Durability

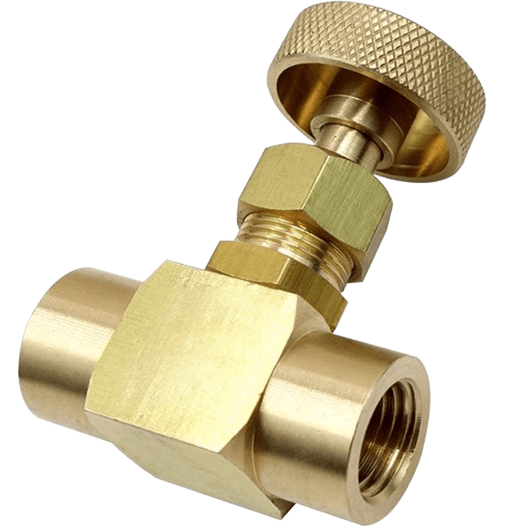

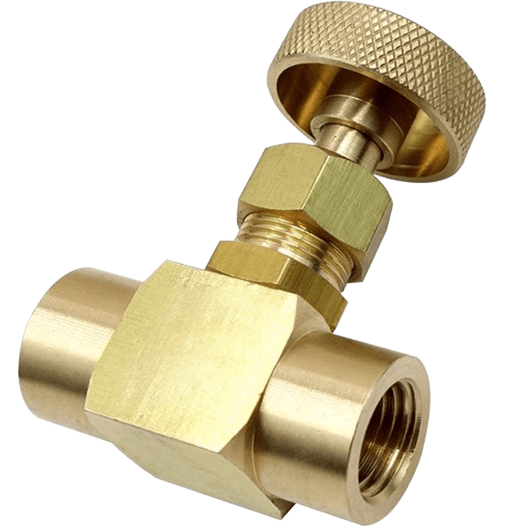

Brass Needle Valves: Suitable for water, oil, and non-corrosive gases. Common in residential and light industrial use.

-

Stainless Steel Needle Valves: Resist corrosion, high pressures, and extreme temperatures. Standard in chemical, petrochemical, and oil & gas industries.

-

Alloy Needle Valves: For specialized environments involving aggressive chemicals or very high temperatures.

.png)

en |

en |